Composite Material Production Techniques: Hand Placement and Autoclave Method

Composite Material Production Techniques: Hand Placement and Autoclave Method

Many techniques are used in the production of composite materials and these techniques determine the final properties of the material. The two most commonly used methods, hand lay-up and autoclaving, have a direct impact on the structural properties of composites.

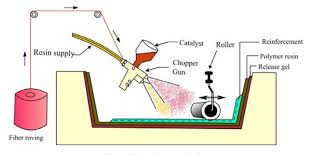

Hand Lay-Up Method:

This method is one of the simplest composite production techniques. In this technique, where the fibers are placed layer by layer by hand, the resin is applied manually and then shaped with the help of molds. The advantage is its low cost; however, the production process can be long and labor intensive.

Autoclave Method:

The autoclave method allows composite materials to be cured under high temperature and pressure. This method is particularly used in the production of carbon fiber composites and results in extremely strong, lightweight and durable products. Autoclave-cured composites are frequently used in aircraft wings, automotive parts and space technologies.

Comparison:

Cost: The manual insertion method is cost-effective, but the autoclave method is superior in terms of quality.

Durability: Autoclaved composites offer high strength and light weight.

Application Area: While hand placement is used in simpler and small-scale projects, the autoclave method is preferred in industrial and precision applications.

The methods used in the production process of composite materials greatly affect the performance of the material. Therefore, it is critical to choose the right method for the application area.